Jelly Candy Depositing Production Line: Streamlining the Creation of Sweet Delights

2023-10-17

Introduction:

Jelly candies, with their delightful flavors and chewy textures, have become a favorite treat for people of all ages. Behind the scenes, the creation of these delicious confections requires a specialized production process, with the Jelly Candy Depositing Production Line playing a pivotal role. In this blog post, we will explore the features, benefits, and significance of the Jelly Candy Depositing Production Line, highlighting how it streamlines the manufacturing of jelly candies, ensuring consistency, efficiency, and delectable results.

1. Understanding the Jelly Candy Depositing Production Line:

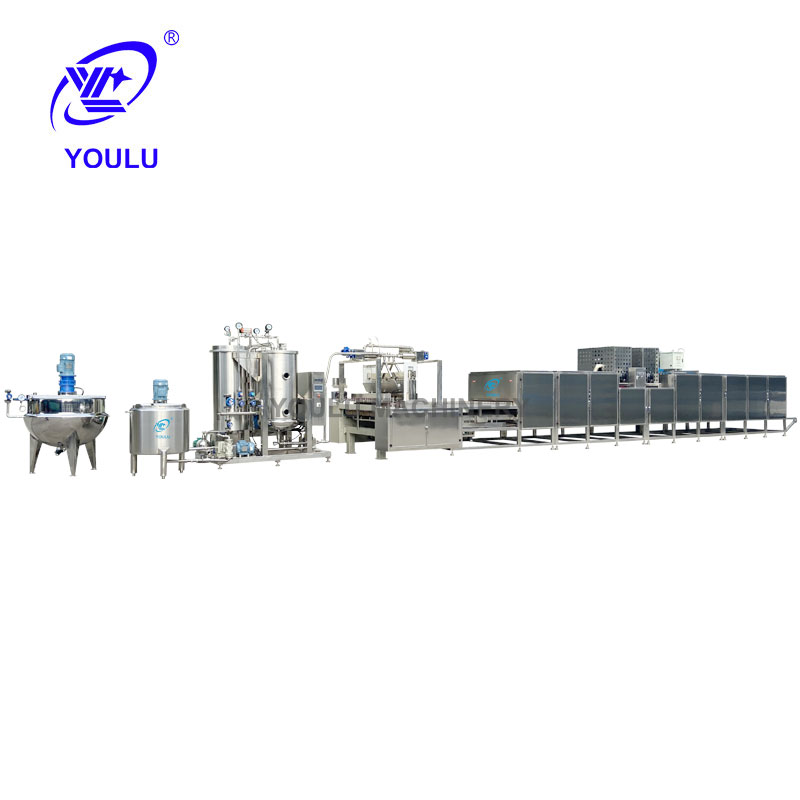

The Jelly Candy Depositing Production Line is a comprehensive system designed specifically for the efficient and precise production of jelly candies. It comprises multiple interconnected machines and components that automate various stages of the candy-making process, from cooking and mixing the ingredients to depositing, molding, cooling, and packaging the finished products.

2. Automation and Efficiency:

One of the key advantages of the Jelly Candy Depositing Production Line is its automation capabilities, which significantly enhance production efficiency. The line is equipped with automated systems that precisely control ingredient measurements, cooking temperatures, mixing speeds, and depositing quantities. This automation eliminates manual errors, reduces labor costs, and ensures consistent quality throughout the production process.

3. Versatility and Customization:

The production line offers versatility and customization options, allowing manufacturers to produce a wide range of jelly candy variations. It can accommodate different flavors, colors, shapes, and sizes of candies. By adjusting the settings and molds, manufacturers can create an array of unique and visually appealing jelly candies that cater to diverse consumer preferences.

4. Precise Depositing and Molding:

The Jelly Candy Depositing Production Line excels in accurate depositing and molding of jelly candies. It utilizes depositor machines equipped with precision pumps or pistons that dispense the jelly mixture into the candy molds with consistent portioning and filling. This ensures uniformity in size, shape, and weight of the candies, enhancing their visual appeal and consumer satisfaction.

5. Cooling and Setting:

After the jelly candies are deposited and molded, the production line incorporates a cooling and setting stage to solidify the candies. This stage may involve passing the candies through a cooling tunnel or using specialized cooling plates. The controlled cooling process ensures the candies retain their shape, texture, and consistency, resulting in the desired chewy and gummy characteristics.

6. Packaging and Quality Assurance:

The Jelly Candy Depositing Production Line typically includes a packaging component that efficiently wraps and seals the candies. This ensures the candies are protected and preserved while maintaining their freshness and taste. Additionally, quality assurance measures, such as inspection systems, may be incorporated to identify and remove any defective candies before packaging, ensuring only top-quality products reach the market.

7. Compliance with Food Safety Standards:

Manufacturers understand the importance of adhering to strict food safety standards, and the Jelly Candy Depositing Production Line is designed with this in mind. The line utilizes food-grade materials, incorporates sanitary designs, and implements hygiene protocols to maintain product integrity and ensure consumer safety.

Conclusion:

The Jelly Candy Depositing Production Line revolutionizes the manufacturing process of jelly candies, combining automation, precision, and efficiency. By automating various stages of production, the line streamlines operations, reduces manual errors, and enhances consistency in flavor, texture, and appearance. Its versatility allows for customization and the creation of a diverse range of jelly candy varieties. With its precise depositing, molding, cooling, and packaging capabilities, the production line ensures the creation of high-quality, visually appealing, and delicious jelly candies. As a result, manufacturers can meet consumer demands, optimize production efficiency, and delight candy enthusiasts with these irresistible treats.